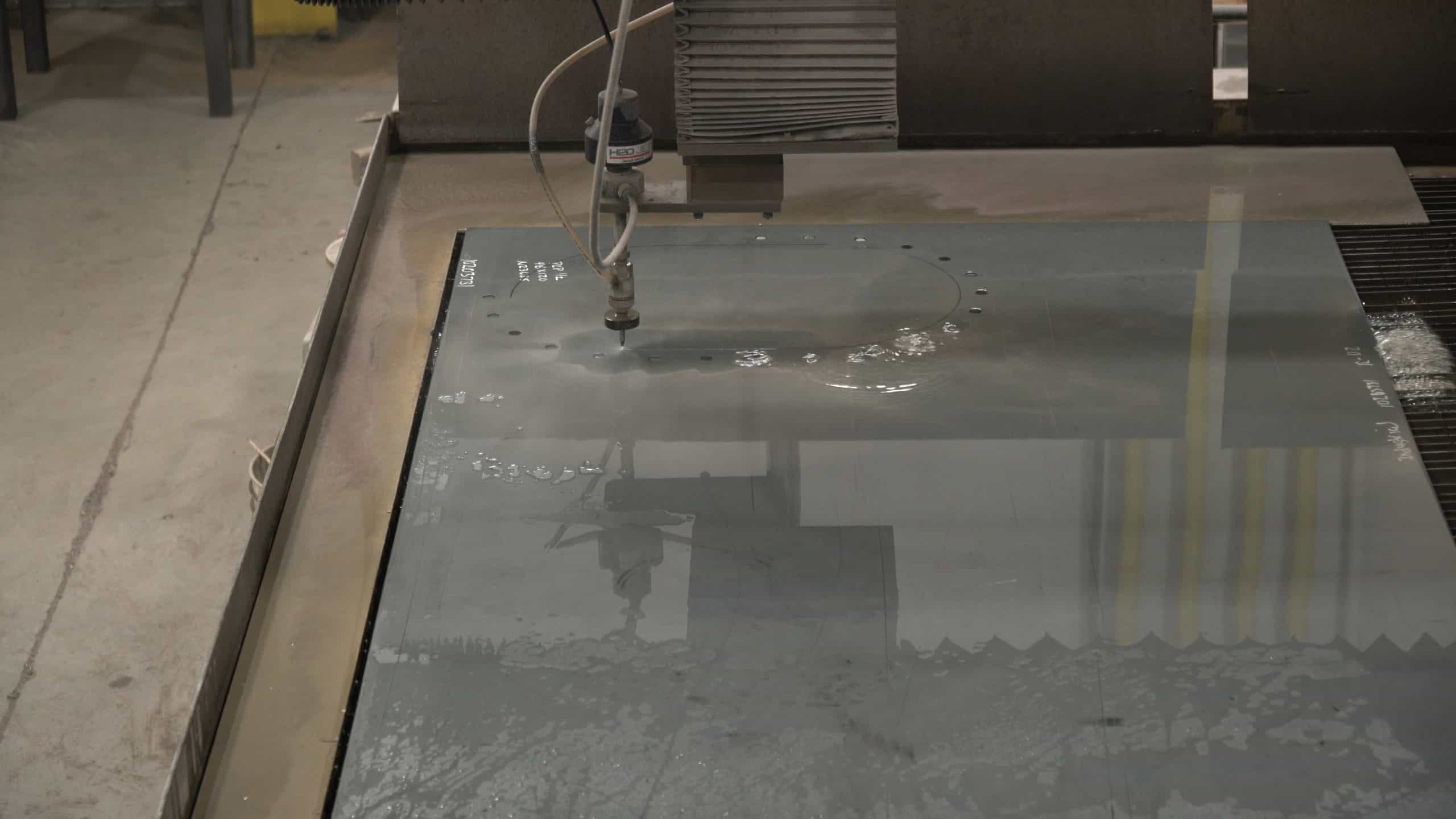

Industrial Resources purchases Jetpoint Technologies, Inc. to expand waterjet capabilities

To further expand its fabrication capabilities IRI purchased Sedro-Woolley-based Jet Point Technologies, owned and operated since 1996 by John Swapp.

“We’ve known John for years,” said Peter Rasco, IRI’s General Manager. “Joining forces could not have come at a better time for both companies.”

Jet Point’s former owner and technicians will now work for IRI in its 15,000 square foot fabrication facility located in Sedro Woolley.

With the purchase of Jet Point Technologies, IRI will add one more waterjet and several skilled staff to its fabrication division, which increases both capabilities and output to serve its growing global customer base.

IRI’s fabrication shop is now home to both Chukar and Flowjet wateriest that are able to cut up to a thickness of 9″(nine inches) with a tolerance of .0003 inches of Marble, UHMW, Aluminum, Stainless, Carbon Fiber, Rubber, Wood, Plastic, Inconel, and Glass. Customers receive final products free of burrs that have a finish quality like no other. IRI produces customer designed parts from materials ranging in thickness from shim stock up to 5 inches.

A waterjet is specialized equipment that utilizes high-pressure water streams to make precision cuts out of raw materials as varied as titanium, carbon fiber epoxy, all-metal alloys, and elastomers. Waterjet cutting is fast, powerful, and precise. The final product will free of burrs and has a finished quality like no other. It is to manufacture parts for handrails, signage, maintenance hole covers, aircraft parts, kayak, and yacht rudders, to name a few.